|

|

||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

Project Description

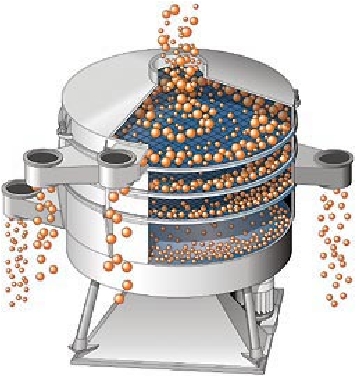

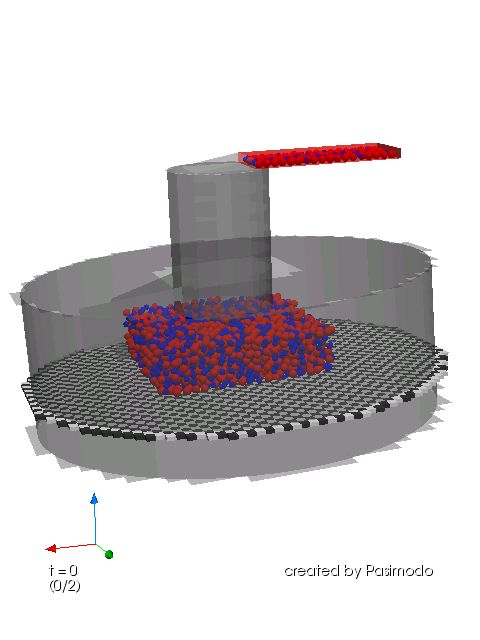

Screening is a basic operation in process engineering.

Almost all bulk goods are screened during their production, i.e. sorted by particle size.

Often, the process of screening is a crucial procedural step for the quality of the final product.

SimulationvideoContact |

| Last modified

15.1.2013 ( |