|

|

|

Institute of Engineering and Computational Mechanics |

|

Pasimodo -

Showroom |

|

|

|

|

|

Research Research

|

|

|

|

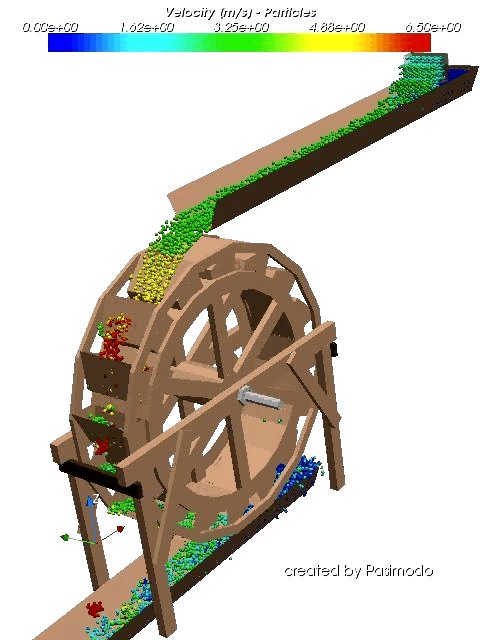

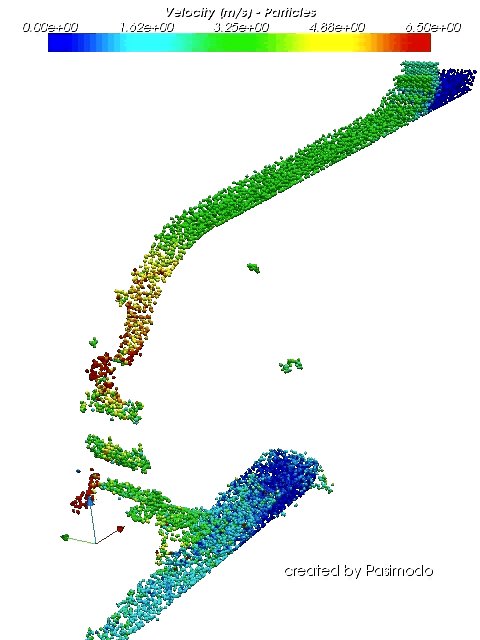

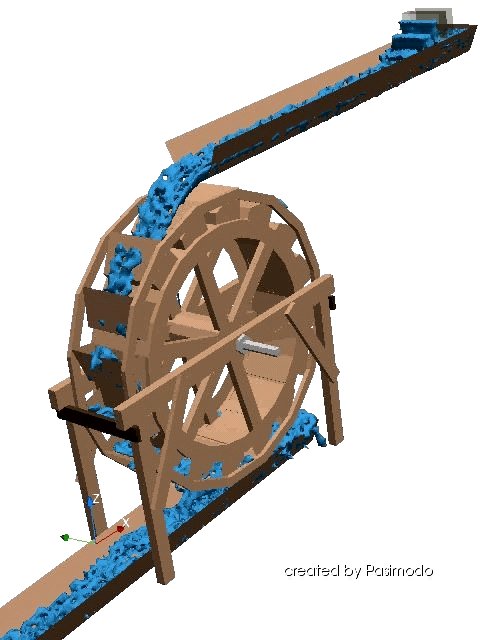

The following simulation examples were created and visualized with the particle simulation

software Pasimodo.

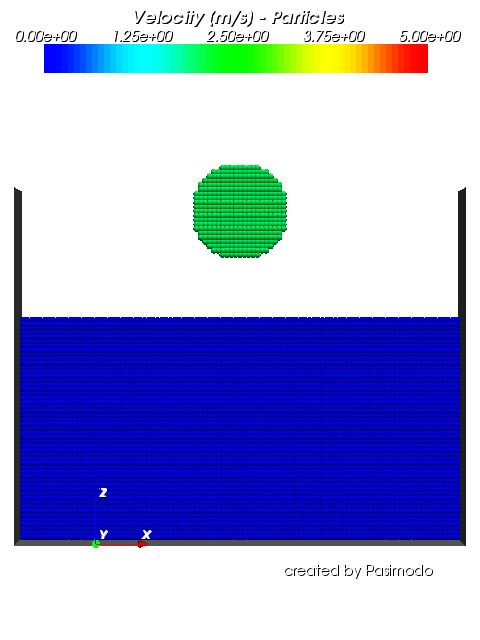

Smoothed Particle Hydrodynamics

-

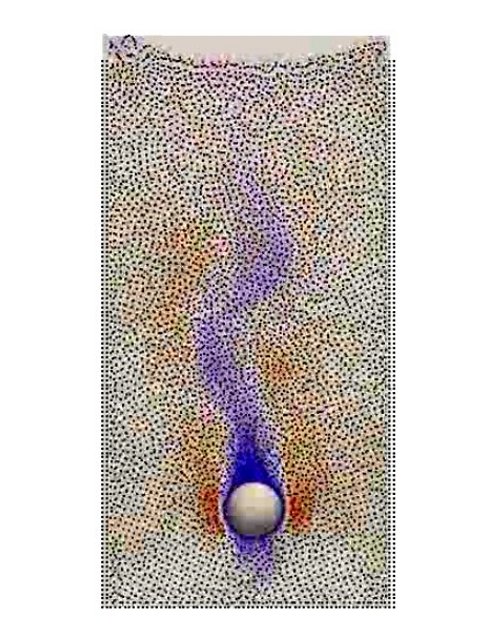

Simulation of a rigid sphere falling in a liquid tank.

Model creation and simulation:

David Vetsch (Laboratory of

Hydraulics Hydrology and Glaciology of Swiss Federal Insitute of Technology

Zurich)

-

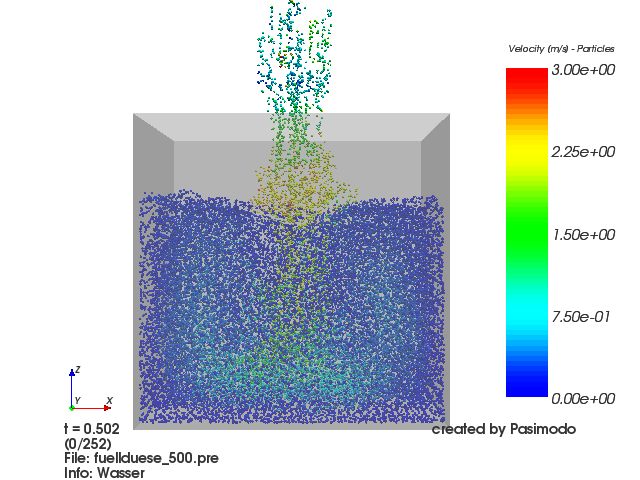

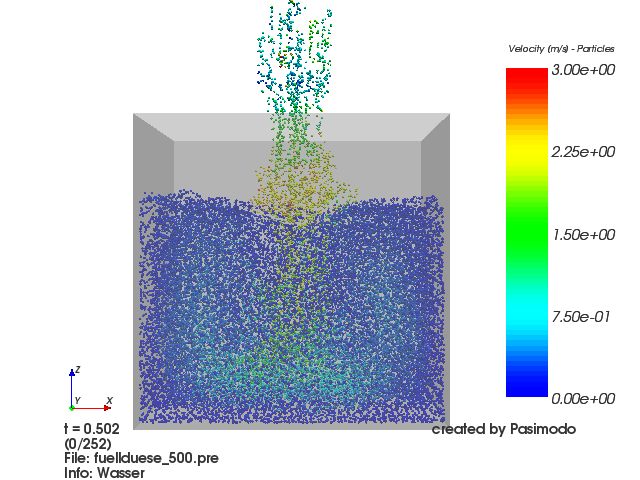

Simulation of a filling process.

The video shows the outpouring of water from a nozzle into a stand-up pouch.

Model creation:

Alexandra

Müller

-

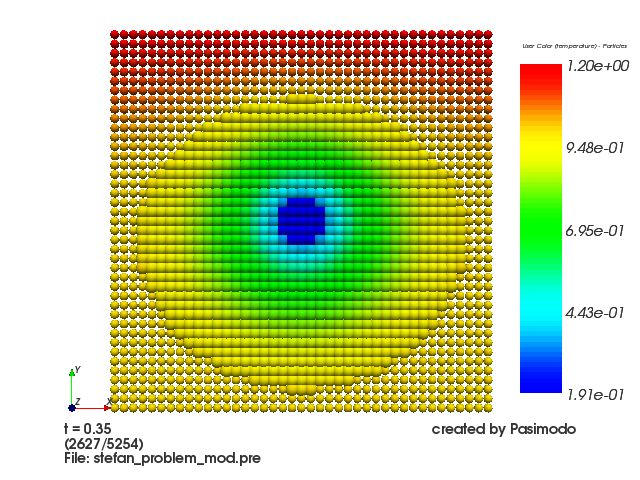

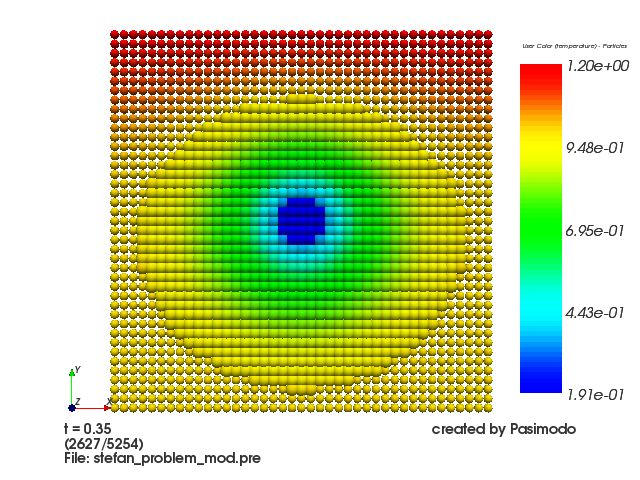

Simulation of a freezing process.

The temperature of the particles on the upper border as well as those in the center is fixed over time.

Frozen particles are shown larger than liquid ones.

Model creation:

Alexandra

Müller

-

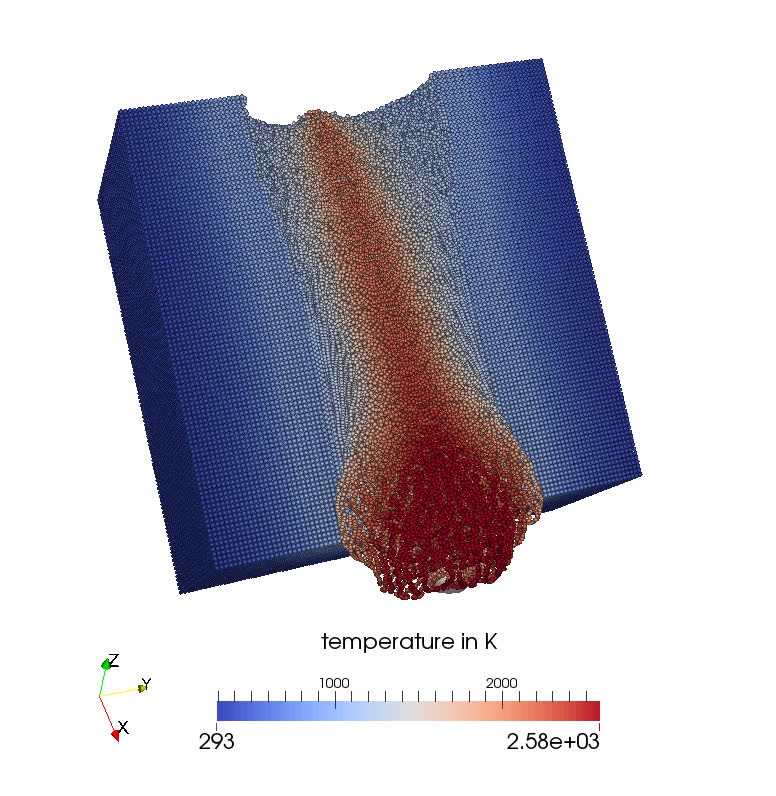

Simulation of a laser welding process of aluminum.

The workpiece is located on an inclined plane and the initial temperature is 20 °C.

During the simulation, a weld pool is formed and the molten material flows downward.

Model creation:

Haoyue Hu

-

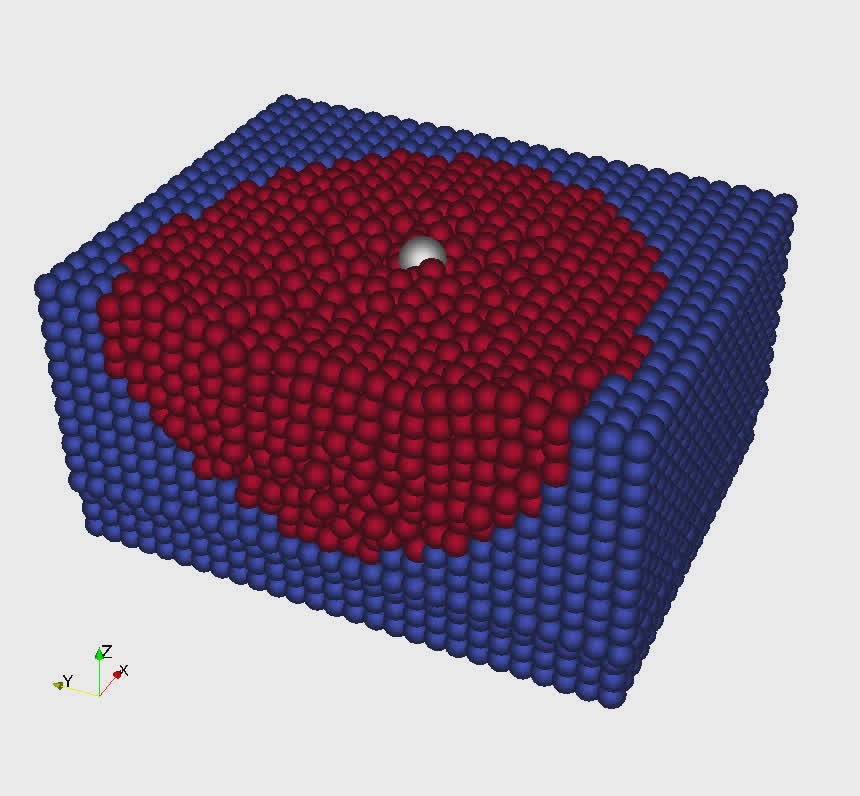

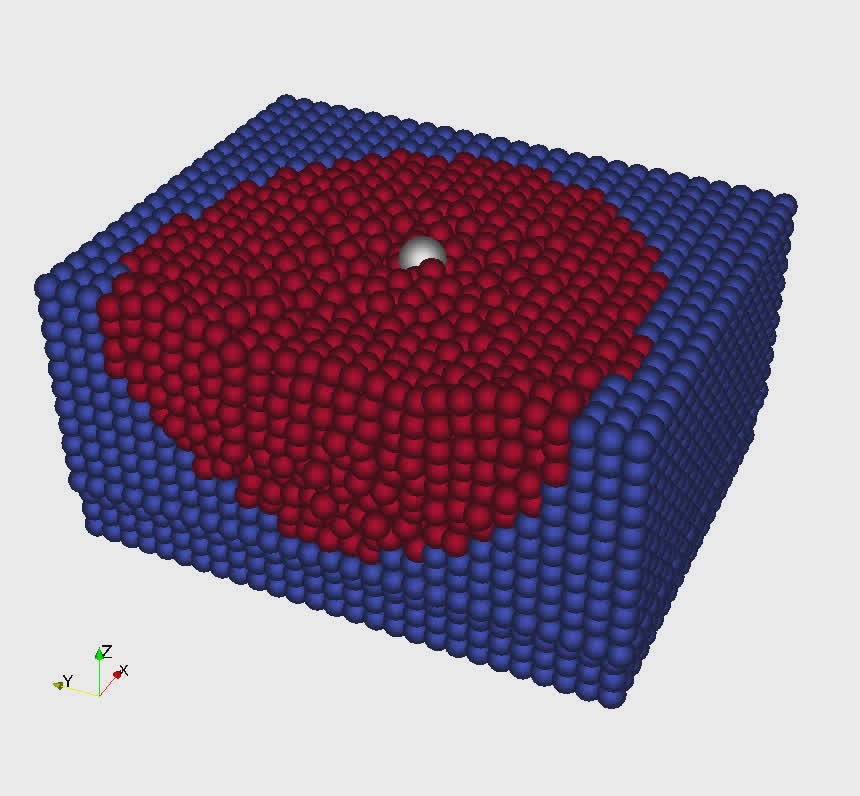

Simulation of a phase transition during laser welding of aluminum.

The blue solid particles behave thermoelastically, whereas the red fluid particles follow the Navier-Stokes equations and form the weld pool.

Model creation:

Haoyue Hu

-

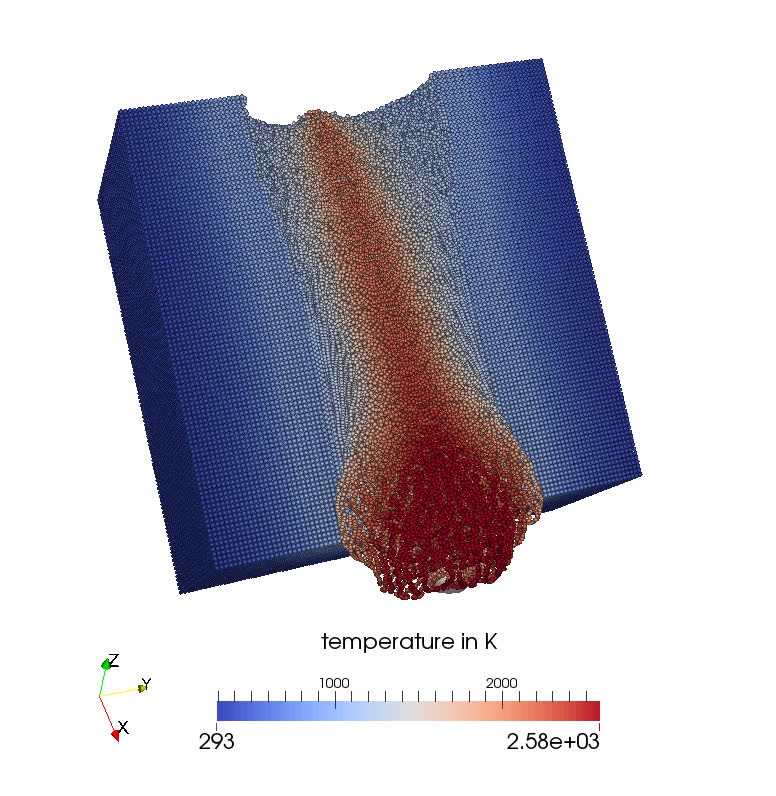

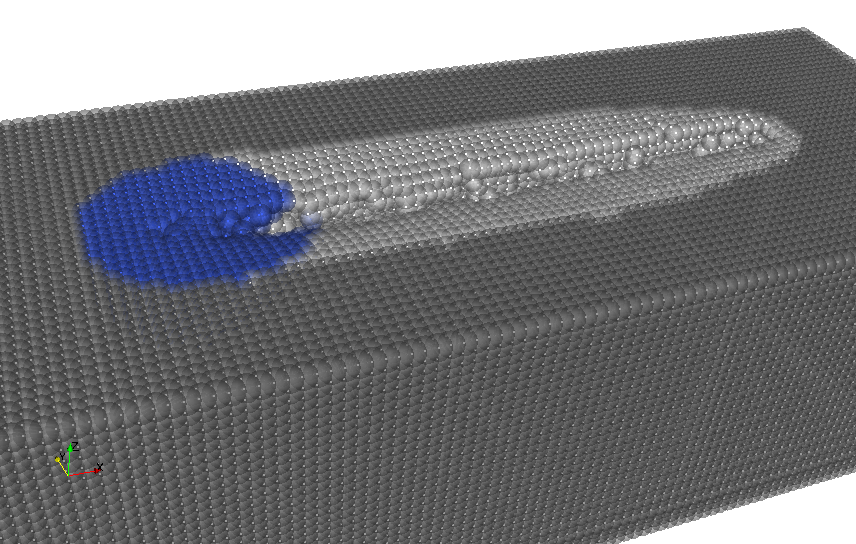

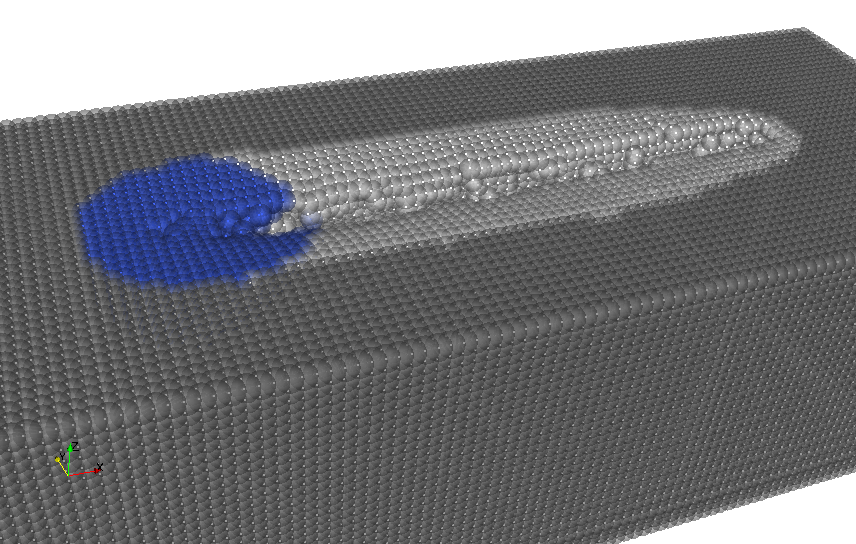

Simulation of deep penetration laser welding of aluminum.

The grey particles form the solid material, the blue particles form the liquid weld pool, and the light grey particles show the resolidified material.

Evaporation is considered through recoil pressure on the liquid melt, the gas phase is currently not modeled.

Model creation:

Haoyue Hu

-

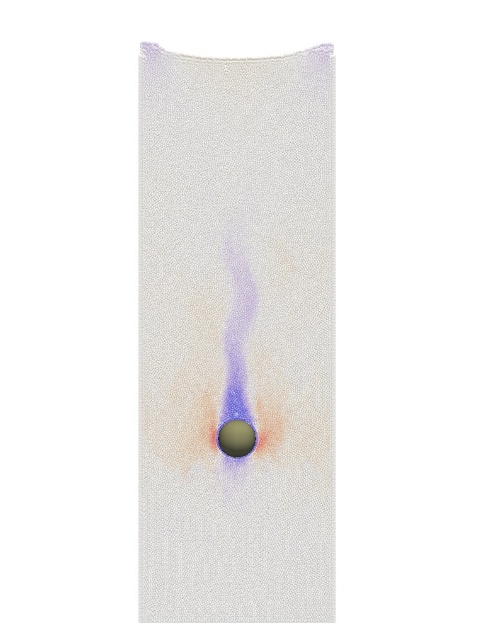

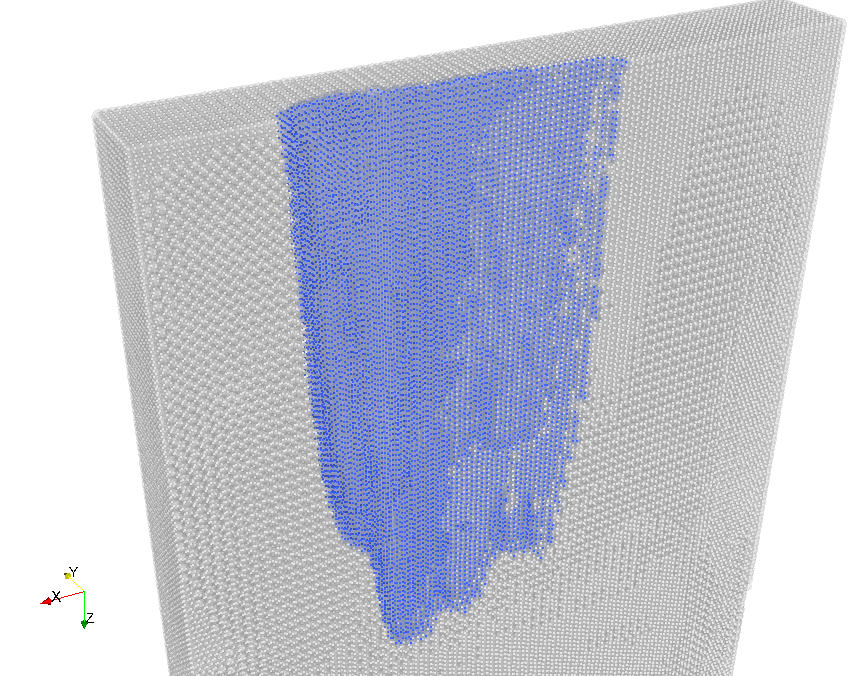

Simulation of deep penetration laser welding of ice.

On the left, the light grey particles form the solid ice block and the blue particles form the liquid weld pool (water).

Evaporation is considered through recoil pressure on the liquid melt, the gas phase is currently not modeled.

On the right, the absorbed intensities (max: red, min: blue) from the laser beam at the capillary front are visualized using a ray-tracing scheme developed at the IFSW.

Model creation:

Haoyue Hu

-

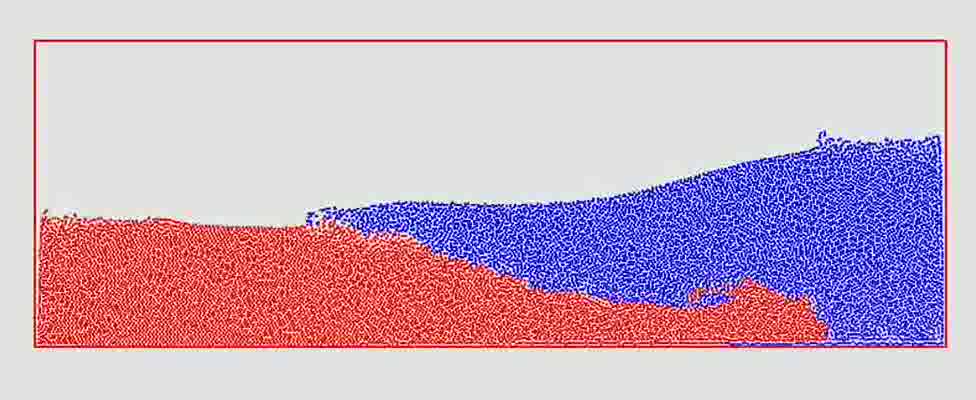

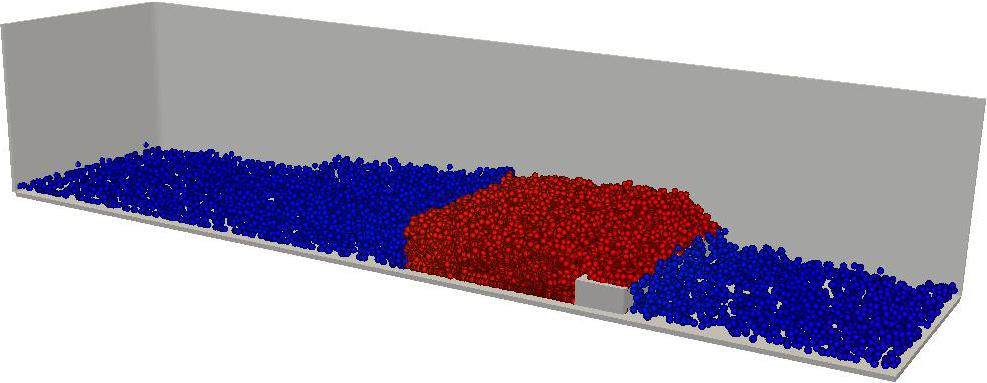

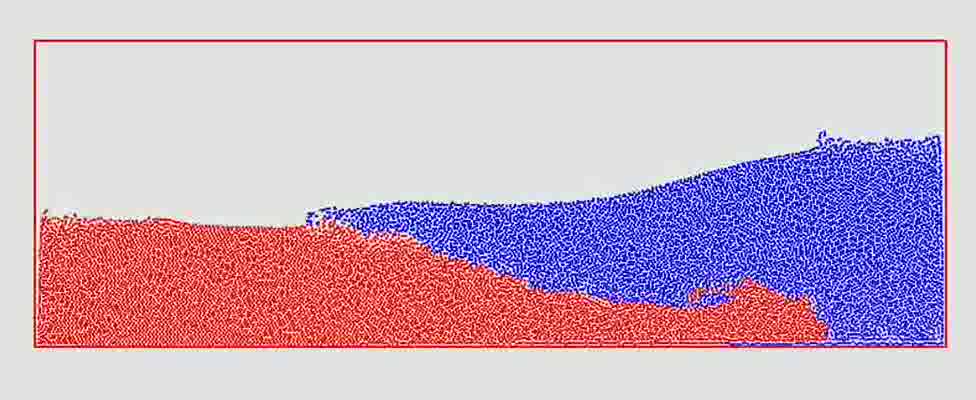

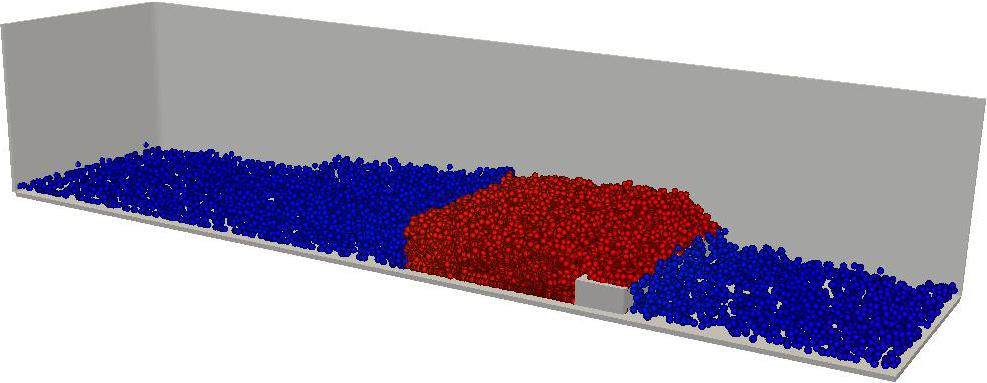

Simulation of two immiscible fluids with different densities in a breaking dam scenario.

Model creation:

Weiran Lin (student research project), Haoyue Hu

-

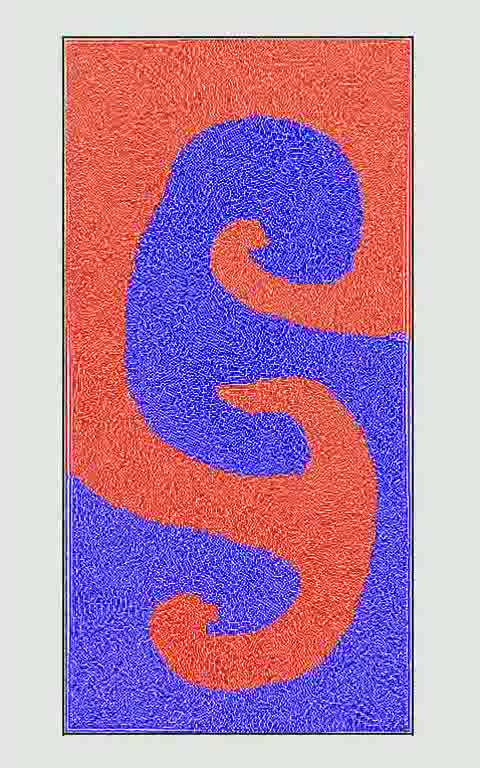

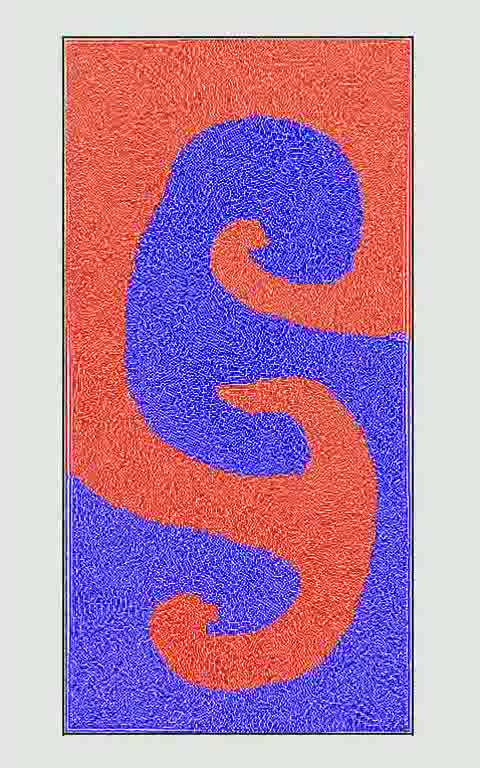

A Rayleigh-Taylor instability occurs at the interface between two fluids of different densities when the fluids are accelerated against each other.

Model creation:

Weiran Lin (student research project), Haoyue Hu

-

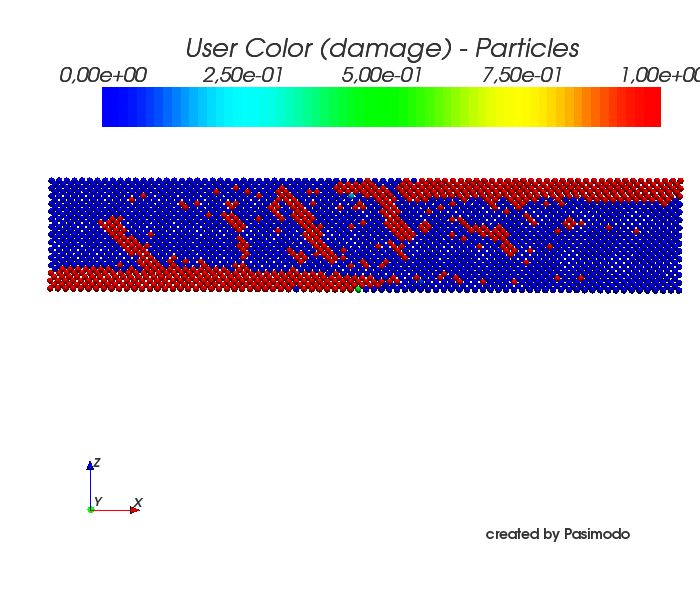

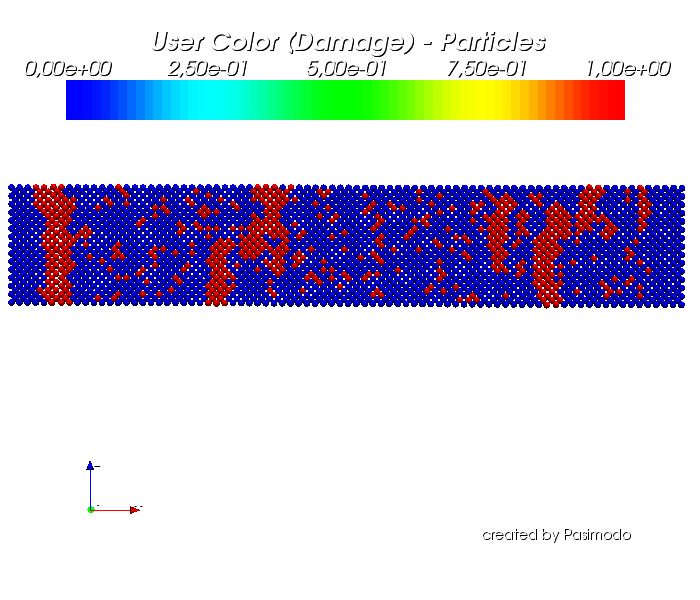

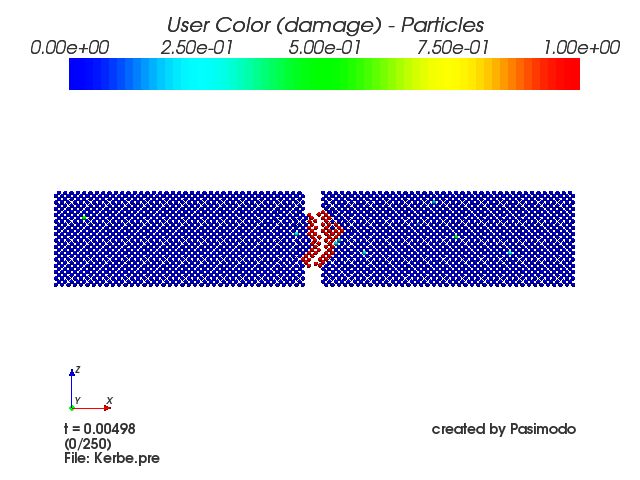

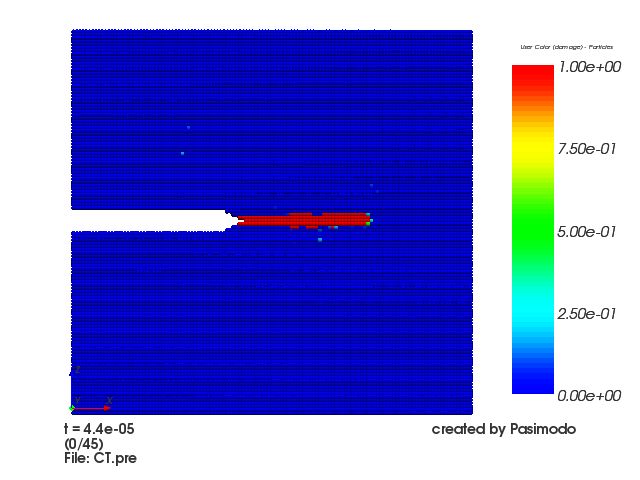

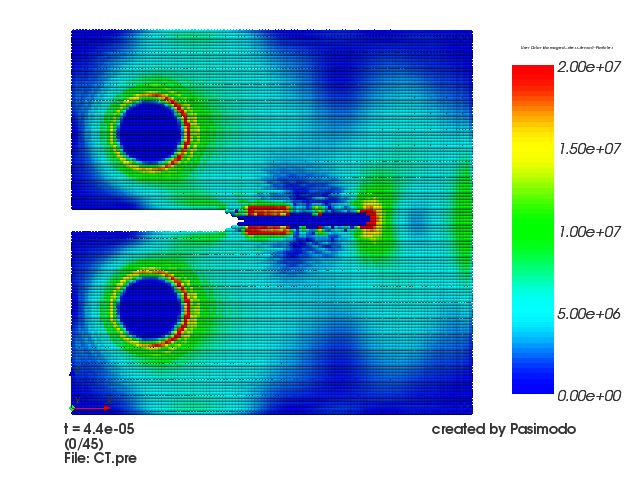

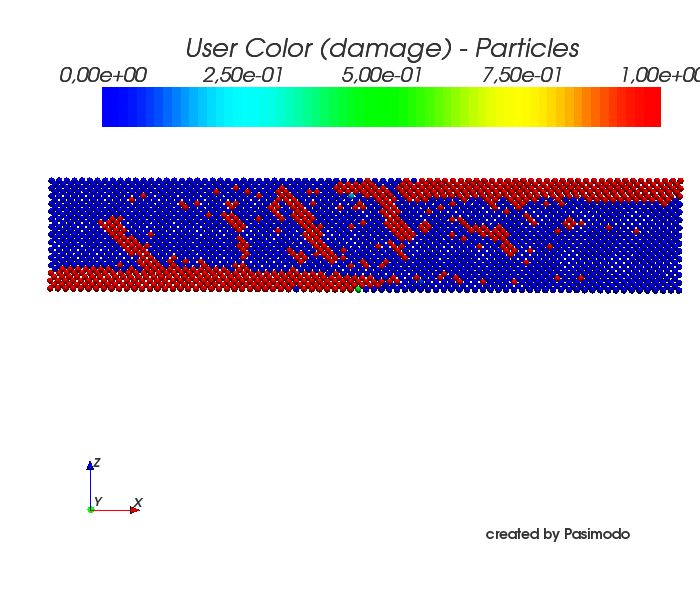

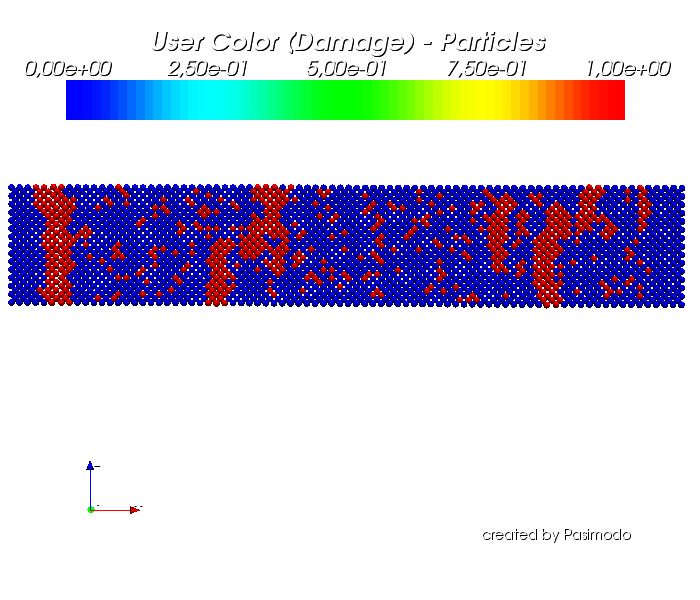

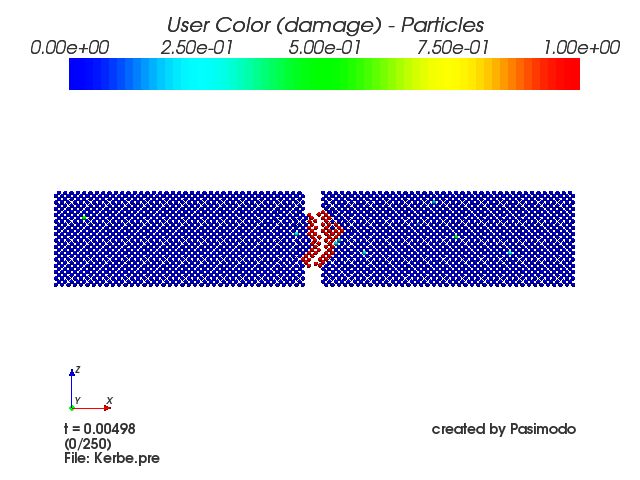

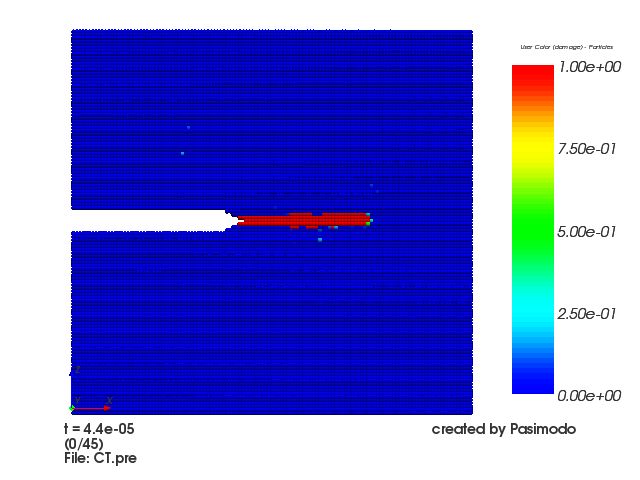

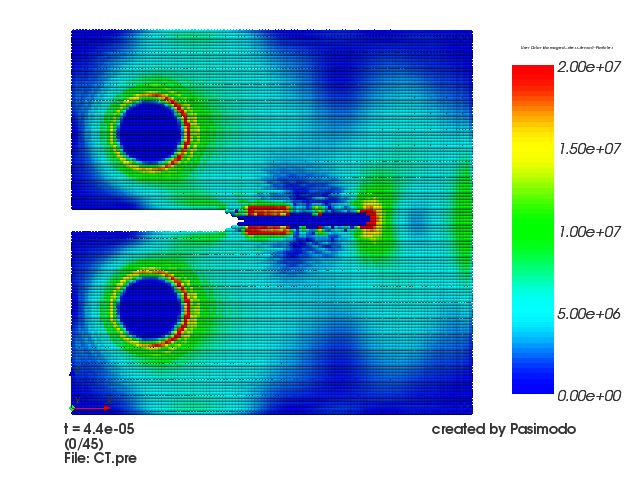

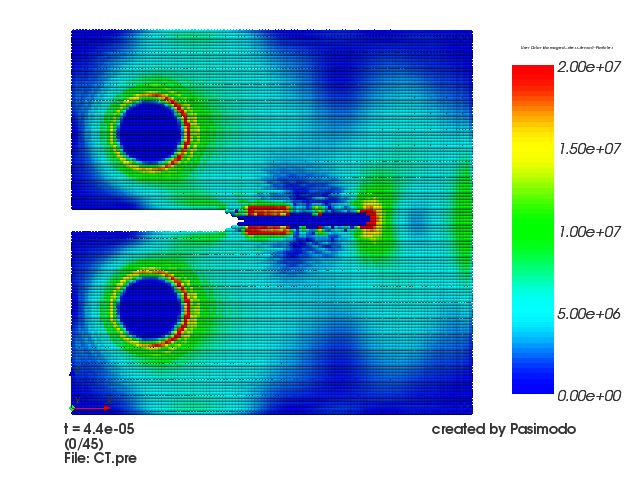

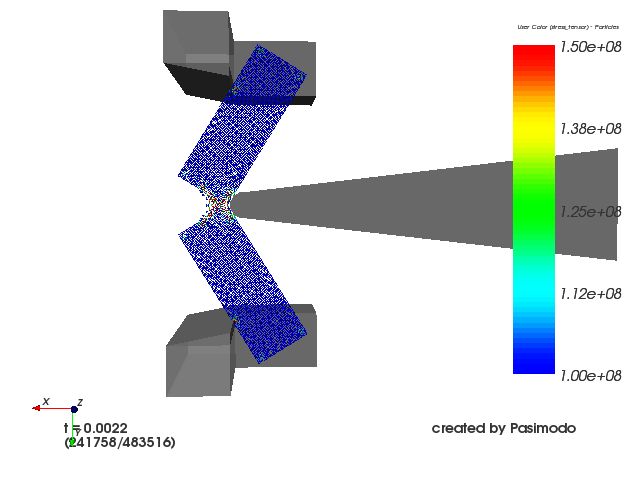

Simulations involving elastic materials including tensile failure.

The particles are coloured according to either damage from 0 (undamaged) to 1 (completely damaged) or von Mises tension.

|

|

|

|

|

|

Shear test of basalt. The material on the upper border is pushed to the right.

|

|

Tensile test of basalt. The last columns of particles on the right are pulled towards outwards.

|

|

Tensile test of basalt with notches.

|

|

|

|

|

|

|

|

Compact tension test (CT test, DIN EN ISO 12737) aluminium.

A notched sample is pulled asunder above and below the notch.

|

|

|

Model creation:

Thomas Erk (student research project),

Alexandra

Müller

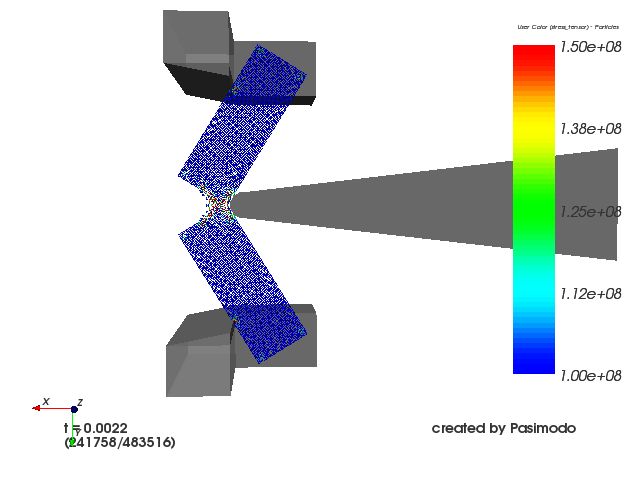

Charpy impact test (DIN 10045) used to characterize the behavior of material AlMg3 under impact loading.

The rigid body model of the hammer deforms the notched specimen and is slowed down.

Model creation:

Fabian

Spreng

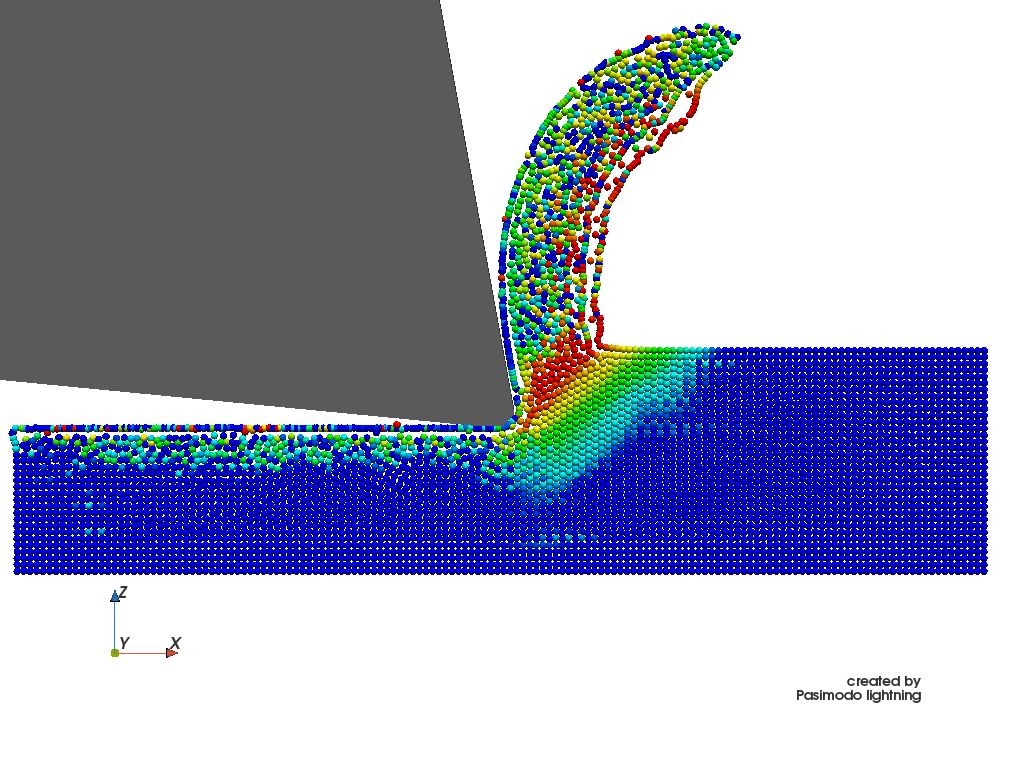

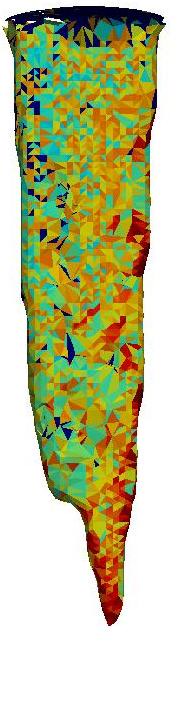

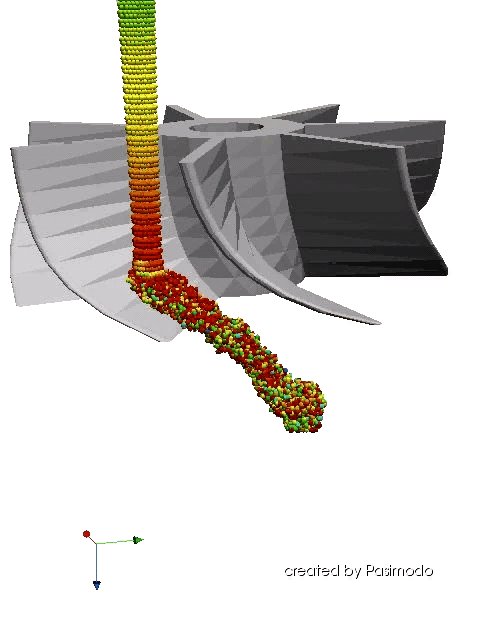

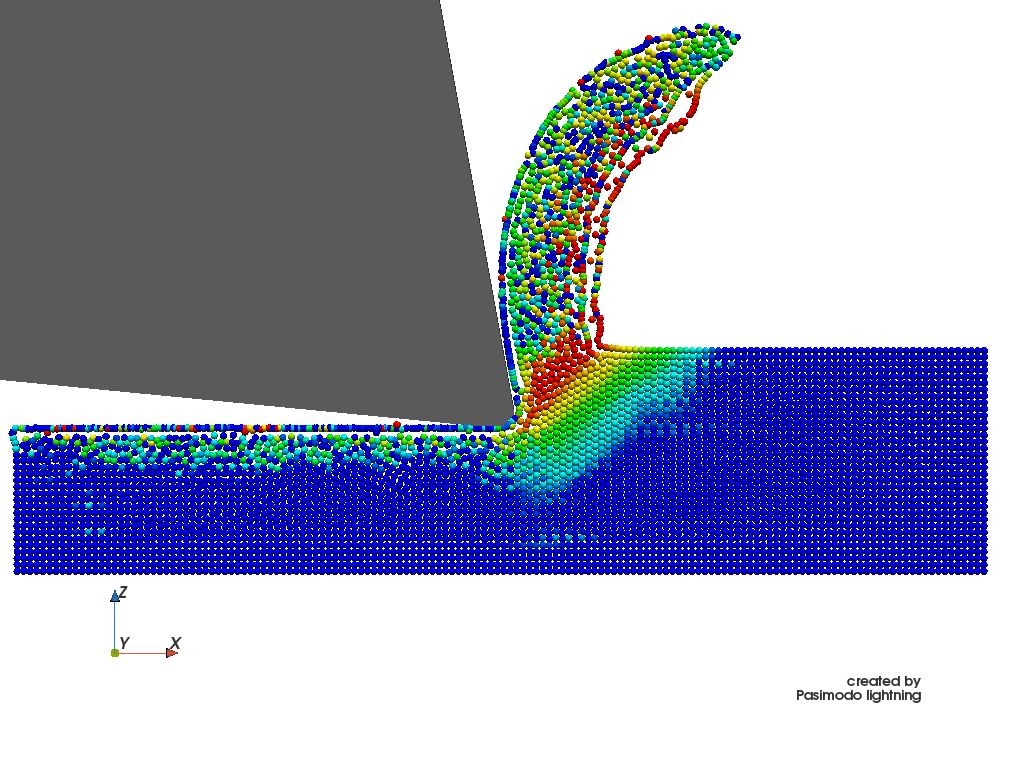

SPH simulation of an orthogonal cutting process for the heat-treated steel C45E with a cutting speed of 1.6 m/s (blue = low von Mises equivalent stress; red = high von Mises equivalent stress).

Model creation:

Fabian

Spreng

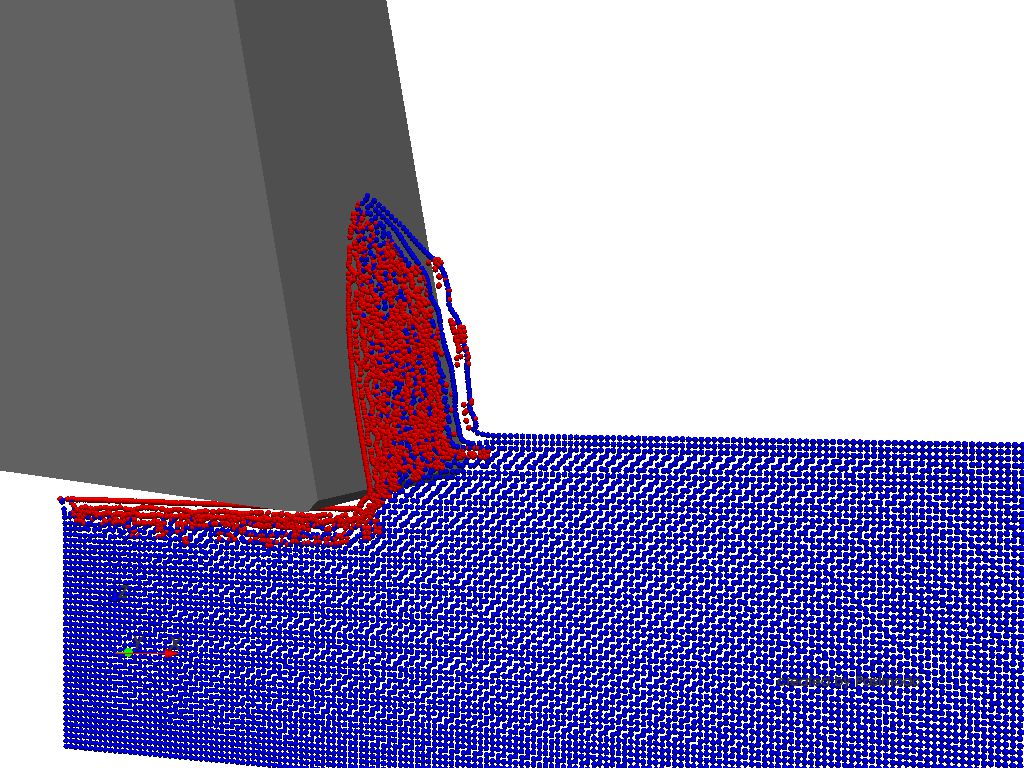

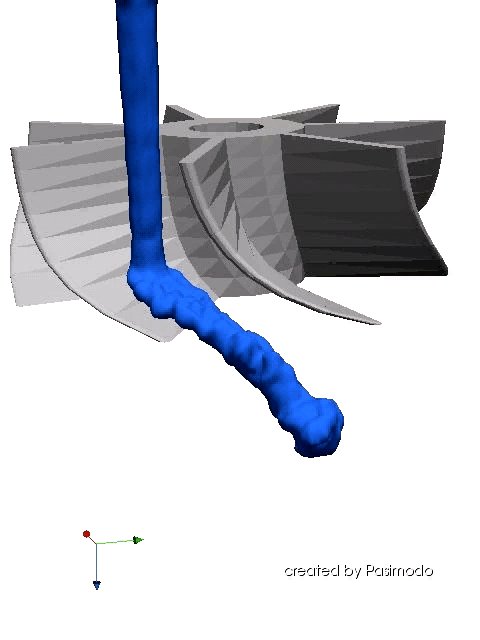

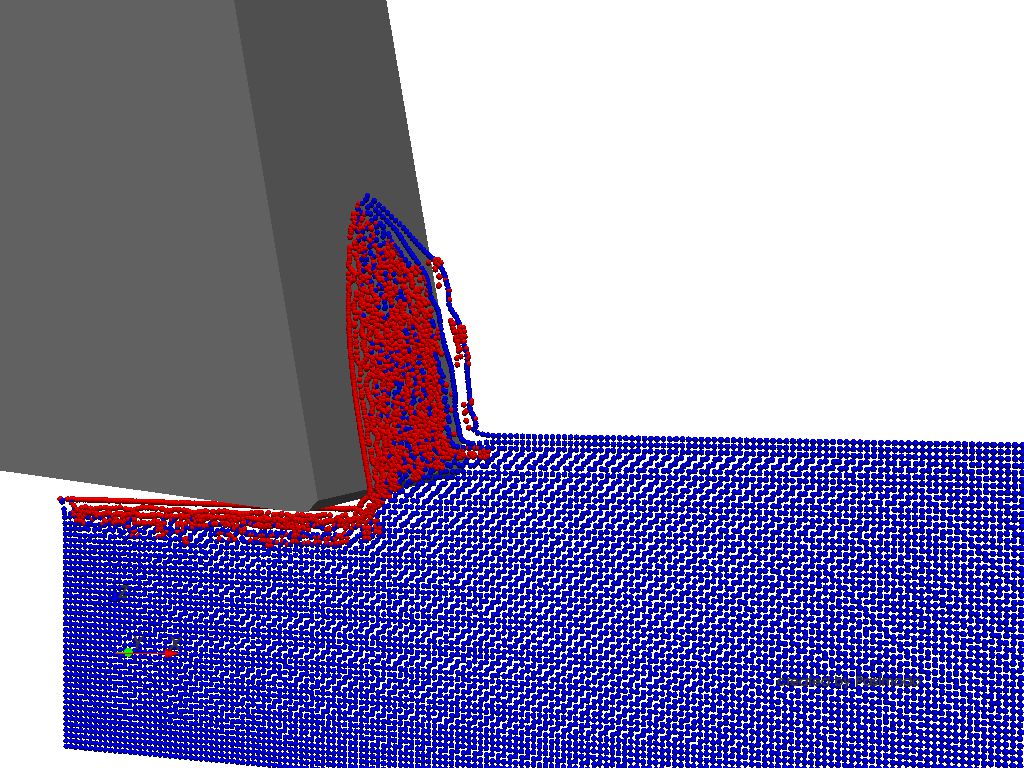

Adaptive SPH simulation of an orthogonal cutting process for the aluminium alloy AlMg3 with a cutting speed of 1.6 m/s (blue = original particles; red = refined particles).

Model creation:

Fabian

Spreng

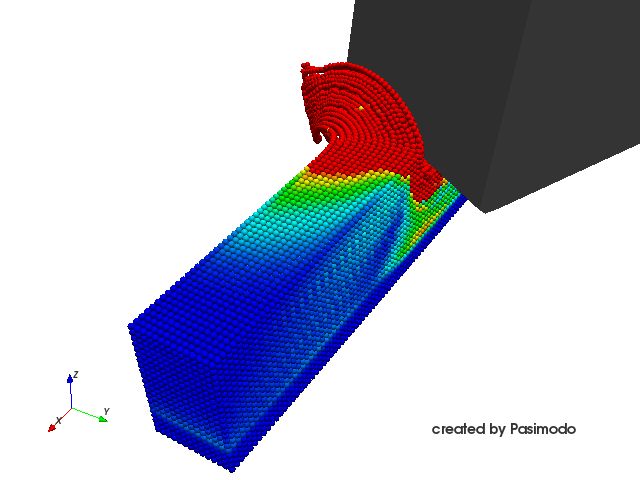

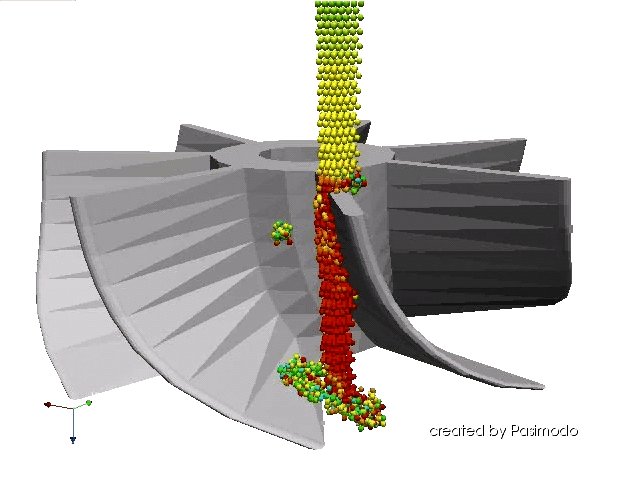

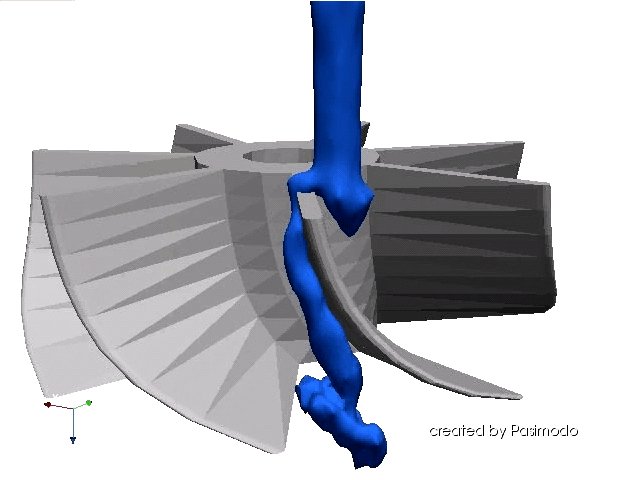

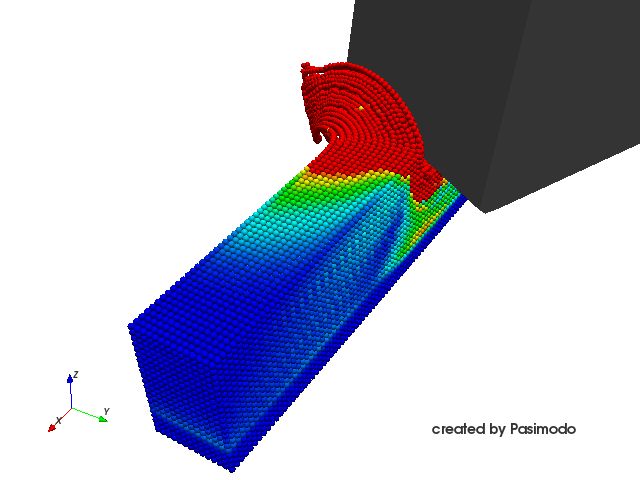

Three-dimensional SPH simulation of a cutting process for the heat-treated steel C45E with a cutting speed of 1.6 m/s (blue = low von Mises equivalent stress; red = high von Mises equivalent stress).

Model creation:

Fabian

Spreng

-

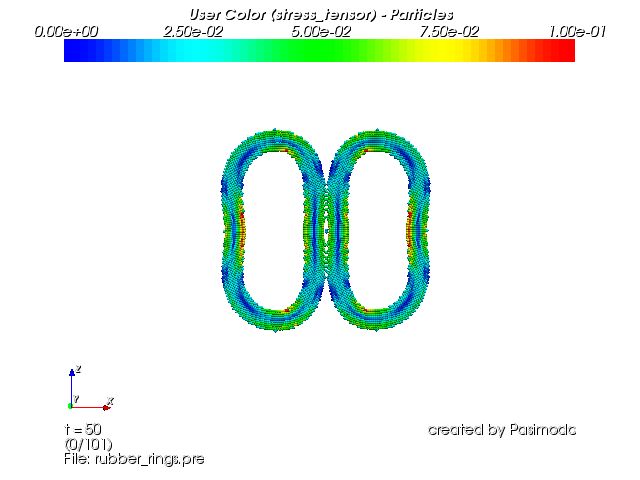

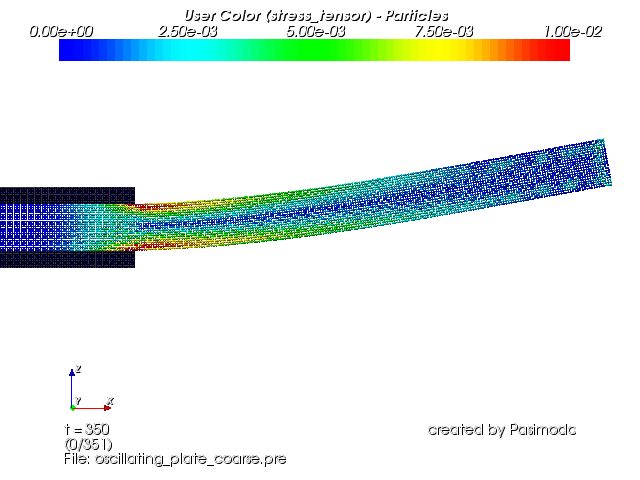

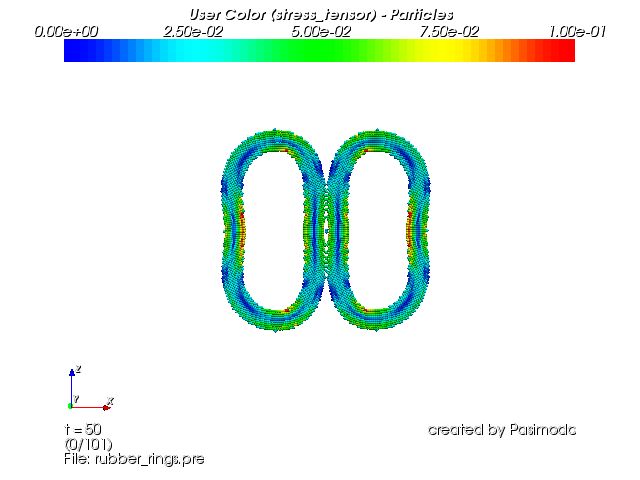

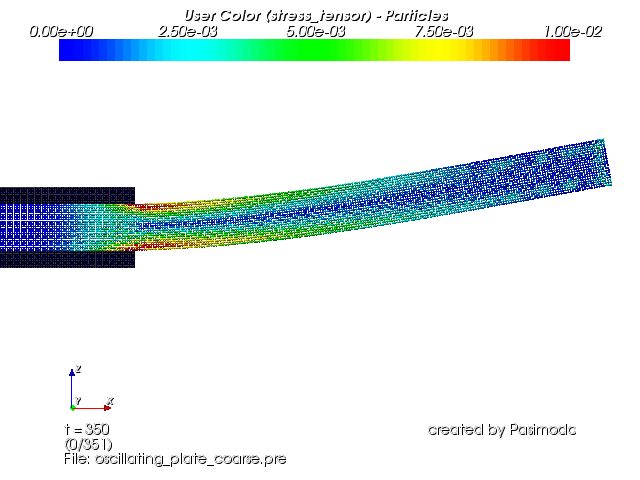

Simulations involving elastic materials.

The particles are coloured according to von Mises tension.

|

|

|

|

Collision of elastic rings.

|

|

Oscillating plate. The plate is fixed on the left end and is deflected on the right side by an imposed velocity.

|

Model creation:

Alexandra

Müller

-

Simulation of sloshing liquids dependent on the viscosity.

Model creation:

Alexandra

Müller

-

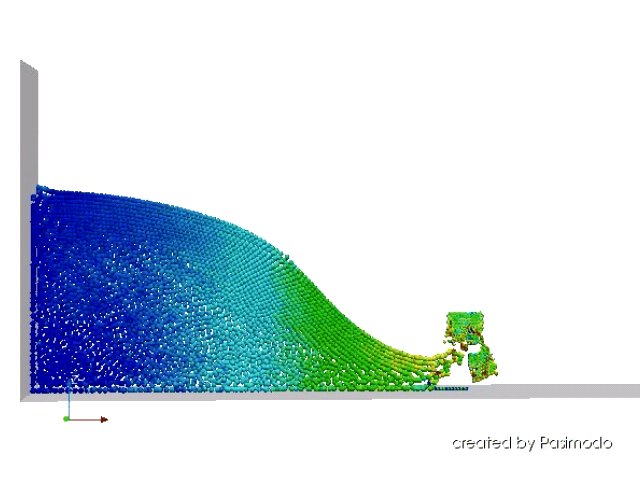

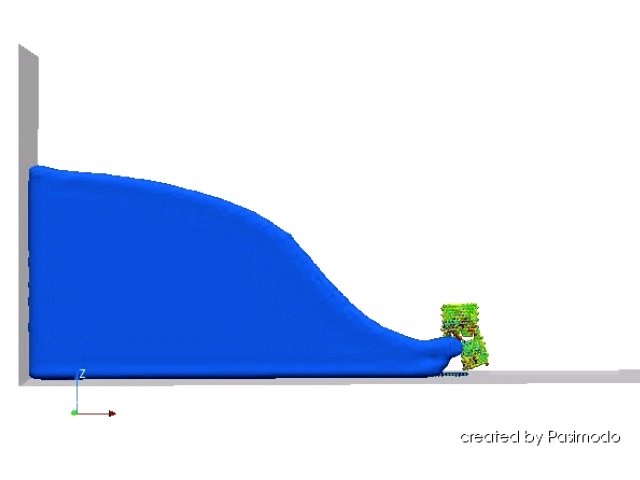

Adaptive SPH simulation of a breaking dam with two obstacles (blue = original particles; red = refined particles).

Implementation SPH-plugin and plugin for adaptive refinement/coarsening:

Alexandra

Müller

Model creation and simulation:

Dirk Schnabel,

Fabian Spreng

-

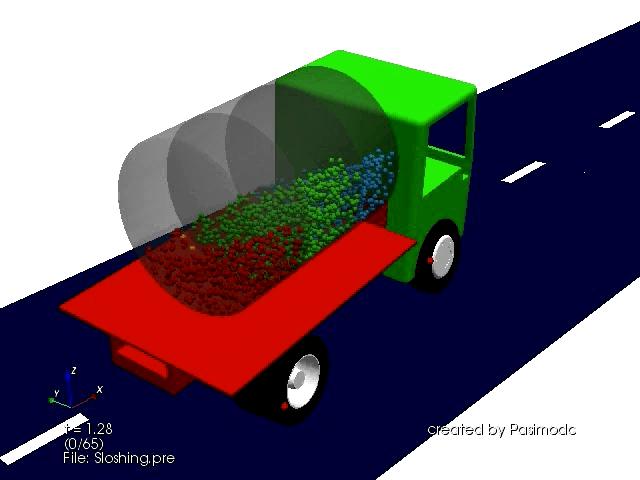

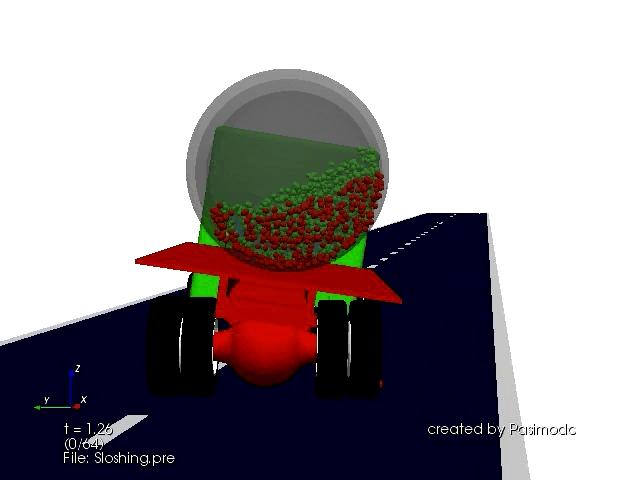

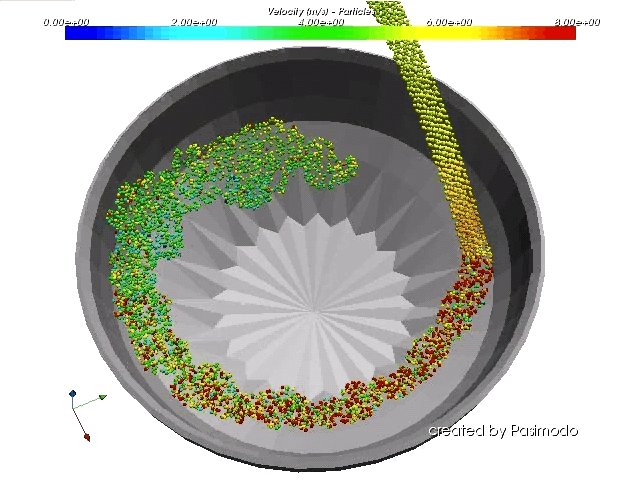

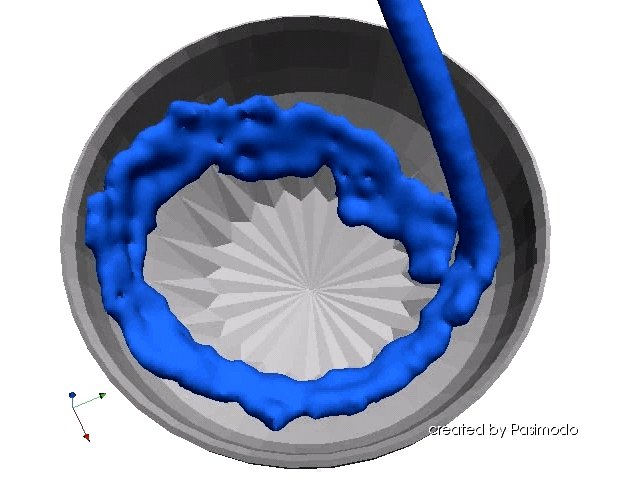

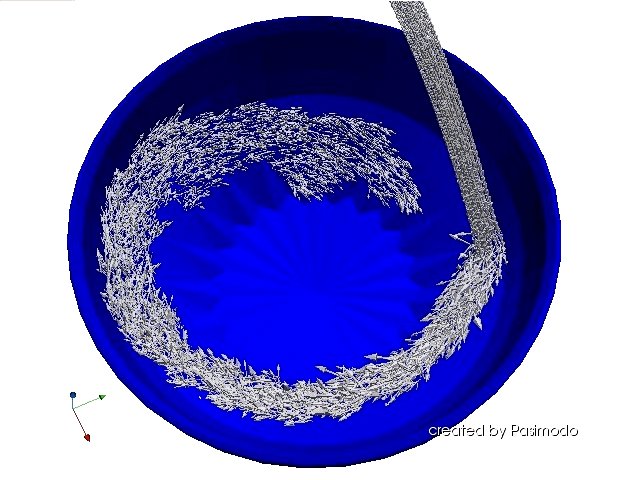

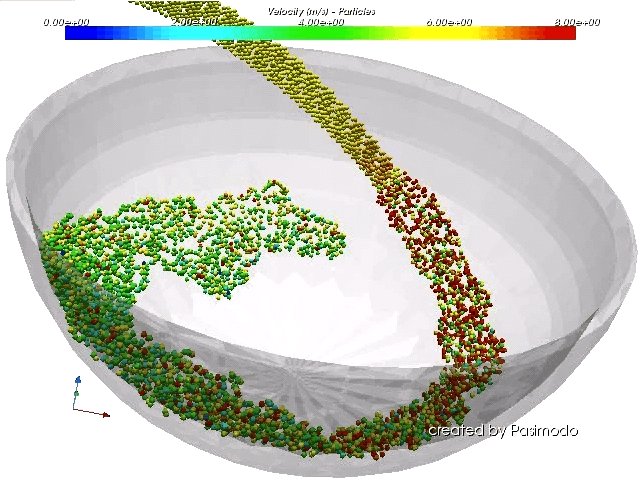

Simulation of sloshing liquids in tank trucks.

Model creation:

Alexandra

Müller,

Florian Fleißner

-

Smoothed Particle Hydrodynamics simulations, some of them coupled with Discrete

Element simulations.

Model creation:

Alexandra

Müller (diploma thesis),

Florian Fleißner

Links

Information about the particle

simulation software Pasimodo.

To the complete Pasimodo Showroom.

Contact

|

|

|

|

|